Rethinking Cell and Gene Therapy Manufacturing

Recent advances in cell and gene therapy (CGT) represent a revolution in personalised medicine, in particular with the regulatory approval of a series of chimeric antigen receptor (CAR) T-cell therapies. These ‘living drugs’ leverage the latest knowledge in cellular engineering and onco-immunology, and provide the immune system of the patient with a significant boost in the fight against tumours. Spectacular results were obtained in young children suffering from acute lymphoblastic leukaemia, but also in adults with other forms of cancers. Altogether, CGT has the potential to cure over 3 million people annually. Unfortunately, most of these patients will not benefit from these life-saving treatment because they are currently incredibly difficult and expansive to produce, typically costing half a million Swiss francs (or $) per patient.

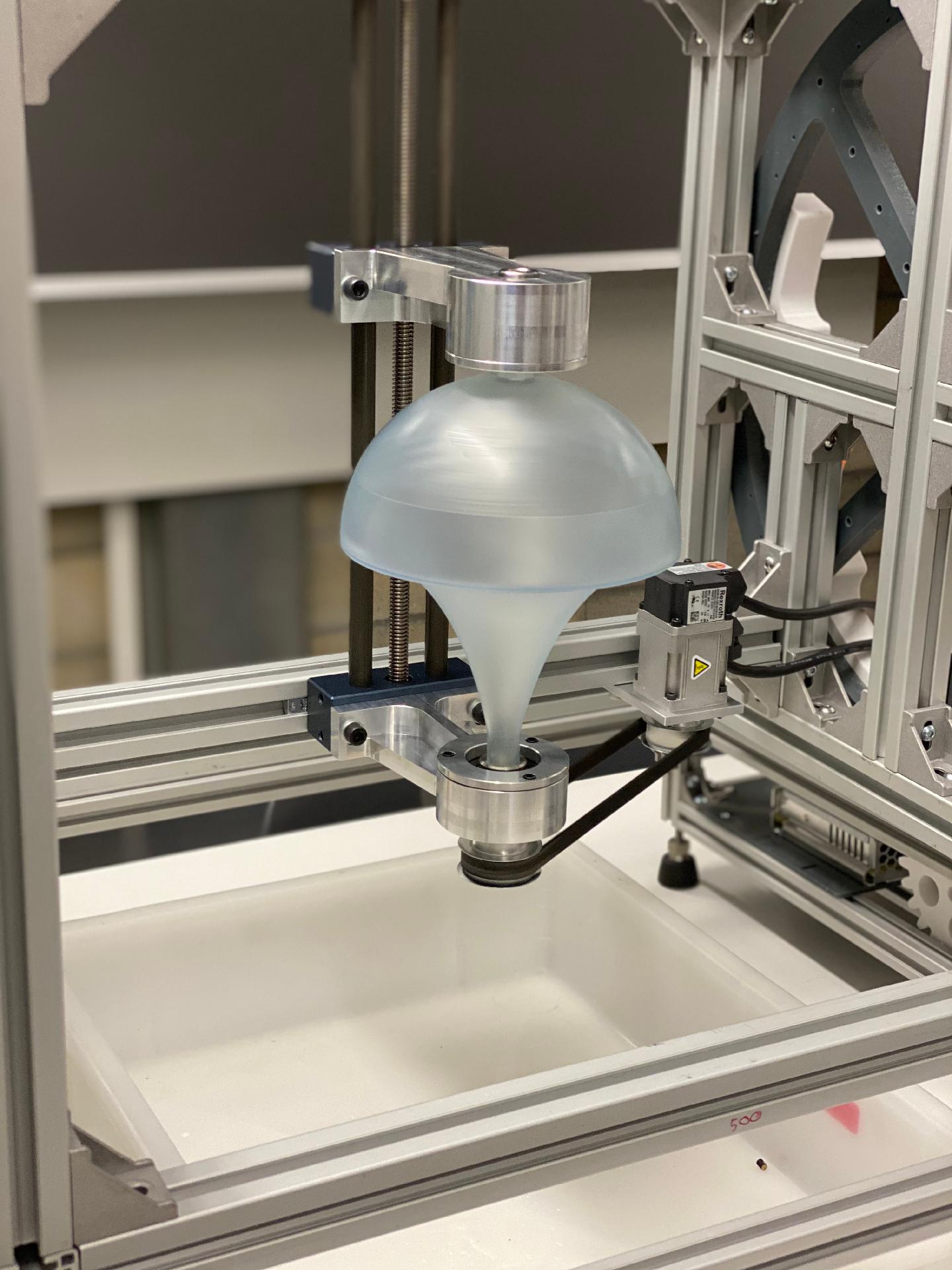

EPFL researchers received generous funding from Innosuisse, the Swiss Innovation Agency, to develop a platform technology designed to standardise and automate CGT manufacturing. By carrying out all steps of this complex process in a single self-contained device, the technology will remove the requirements for large sterile facilities that are costly to build and maintain. It also minimizes errors due to human interventions. The solution developed in cooperation with researchers at the University of Geneva and the University of Applied Science in Yverdon (HEIG-VD) will bring the production closer to the patients, save time, cut costs, simplify logistics and ultimately increase the safety and accessibility of these personalised treatments. Such a platform will address the needs of organizations involved in the development of new CGT products, from pre-clinical research to commercialization, and is a key component of a scalable solution to rapid and safe manufacturing of CGT from a patients’ own cells.

“Every pharmaceutical company we talk to is actively looking for a solution that can simplify their process development. There is a clear and urgent need, and we are thrilled to now have the means to validate our idea with a proof-of-concept,” says Dr. Yann Pierson, the initiator of the project and inventor of the technology. Led by Dr. Pierson and his colleague Dr. Luc Henry, the project is hosted in the laboratory of Professor Matthias Lütolf and is supported with a budget of CHF 650,000. This funding will allow EPFL researchers to work hand in hand with industrial automation engineers from HEIG-VD and onco-immunology experts at the AGORA Translational Cancer Research Center hosting the Swiss Cancer Center Léman (SCCL) in Lausanne.

Developing such a complex device requires a highly interdisciplinary team. "We were determined to bring the right researchers on board to maximise chances of success. The AGORA community is the perfect environment for such a project. A mix of world-class institutions hosting experts in all domains required to achieve this technological feat,” says Dr. Henry.

A team led by Prof. Didier Maillefer at the HEIG-VD will develop and test a range of technologies necessary to enable key features of the device. The platform will then be tested for the production of a benchmark CAR T-cell therapy at AGORA, in the laboratory of Prof. Denis Migliorini, under the supervision of Dr. Valérie Dutoit, two specialists of medical oncology at the faculty of Medicine at the University of Geneva. The Brain Tumor and Immune Cell Engineering Group led by Prof. Migliorini develops next generation CAR T-cell therapies against glioblastoma multiforme (GBM), a malignant tumour affecting the central nervous system.

“Automation is one of the greatest challenge in the development of CAR-T cell therapies.

We now have a platform that can be readily tested in parallel to the standard manual production techniques. Our goal is to streamline the manufacturing process of clinically approved GCTs,” says Prof. Migliorini.

The proof-of-concept financed by Innosuisse will allow collecting critical biological data, paving the way towards the future commercialisation of this technology. A company, Limula SA, will be later involved in order to guarantee that the technology is developed beyond the collaboration, and successfully commercialised, with the goal of delivering a scalable and cost-effective manufacturing platform as soon as possible in order to help bring more CGT products into the clinic for the benefits of patients.